|

|

|

|

|

|

|

|

Ever since the creation of the GR-5A engine I have wanted to expand on my research by making a follow up project, the GR-6. This new turbine would feature several design improvements over the previous with emphasis on durability and increased power. When I had completed the GR-5 I was more interested in building the GRV-1 “Turbotug” although the ideas I had conceived for the GR-6 had not left my head. Now that I have completed several more chapters of my research I believe I am ready to start the GR-6 and hopefully use what I have learned to develop a more advanced design.

It has now been ten years since I started work on the GR-5 engine and I have gleaned a lot of knowledge from my experiments. I am eager to learn more with this new project and I am glad I can share this adventure with my loyal readers ;0)

|

|

|

|

|

|

|

Over the last few months I have been searching for and acquiring parts for this build, mostly over the internet. I have won over 50 eBay auctions and still trying to win more ;0)

|

|

|

|

|

|

|

|

There are several goals I want to achieve while developing the GR-6 which are the following:

#1 My first goal is to modify the GR-5 combustor design to use liquid fuel in lieu of propane gas. The GR-5A currently uses liquid propane fuel which is pressurized to maintain it’s liquid state. This inherent pressure is what eliminates the need for a fuel pump on the GR-5A engine. The pressure in the LP fuel tanks delivers the propane gas into the engine’s combustor but comes at the cost of inconsistent fuel pressure. As the propane tank empties it’s expanding LP gas absorbs heat and cools the tank dramatically. This cooling effect causes a pressure drop as the fuel is less willing to “boil” off and turn into gas when in a cold state.

Because of this fuel pressure issue I want to build a liquid fueled combustor design that will deliver consistent power without freezing up fuel tanks. I want to modify my original combustor design to be used with an atomization type fuel injection system. This type of fuel delivery is used on commercial jet engines and is the most reliable in terms of longevity. It is not commonly used on home-built turbines as it is difficult to get a fine enough atomization to allow complete combustion in such relatively small combustion chamber. This will take a specially designed combustor and a higher than usual fuel pressure to feed a fuel nozzle for this design.

This fuel modification will make the new GR-6 engine more reliable and reduce the danger of pressurized fuel tanks.

|

|

|

|

|

|

|

|

#2 The next modification to the GR-5 design is to implement a new “spin” on an old type of starter system. I have learned trough my research that the least amount of “contact” with the rotating assembly of the turbocharger during startup is the best way to prevent bearing wear and vibration within the turbine assembly. The simplest and most reliable starter system used on DIY turbines is that of the “windmill” type where air is forced into the turbine to spool up the engine. With this design there is no direct contact with the turbine which prolongs the engine’s overall service life.

I want to revamp my GR-5A starter blower system with a modern model airplane ducted fan blower (seen below) which can move quite a bit of air for it’s size. The 1+ horsepower brushless Electric Ducted Fan or EDF unit I will be using was originally intended to power model jet airplanes, something I am familiar with ;0)

|

|

|

|

|

|

|

|

#3 The next modification to the GR-5 design will be to use more resilient alloys in the construction of the combustor and power turbine assemblies. By using stainless steel instead of carbon steel I can eliminate the need for surface protection against corrosion. This upgrade will make the engine last much longer however the cost is considerably higher than what was used on the GR-5 project.

I have acquired a small stockpile of 304L stainless steel tube and sheet steel at my shop (seen below) for this build, some of which was left over from my GR-7 project.

|

|

|

|

|

|

|

|

#4 The next design change is to utilize more modern electronics than what was used in the GR-5A project. There’s no arguing that the GR-5A’s electromechanical logic ECU is as simple as it gets. There is room for improvement with the possible addition of a programmable microcontroller that would reduce the ECU’s size and improve functionality of the system.

|

|

|

|

|

|

|

|

#5 My next goal is to improve the efficiency of the GR-5’s power turbine design. The old design is capable of about 8 shaft horsepower and my hopes are to beat that by at least 25%. My plan is to build a slightly larger turbine wheel with a better pitch design coupled to a 4:1 inline gearbox (seen below).

|

|

|

|

|

|

|

|

#6 My last goal is to make the GR-6 as compact as possible so it may be used as a powerplant for a future research vehicle. The GR-5A is quite large considering it’s power output which is why I want to tighten up the configuration a bit on this next design.

|

|

|

|

|

|

|

|

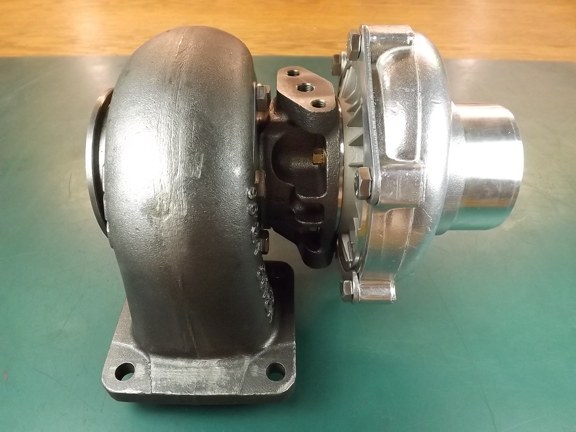

The GR-6 will be based on a T04B automotive turbocharger much like the T04B90 used on the GR-1/GR-5 engines.

|

|

|

|

|

|

|

|

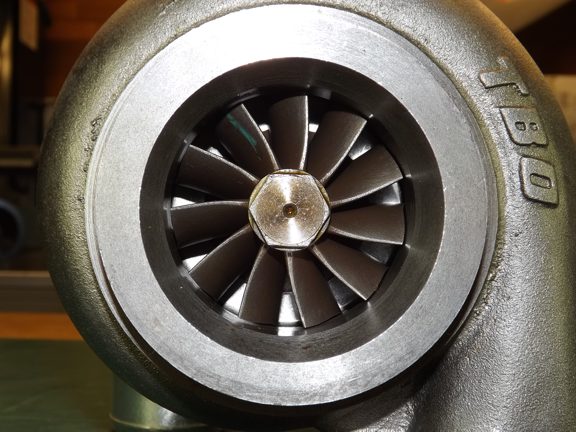

I picked up this import T04B for about $240 (shipped) on eBay. It features a V-trim compressor wheel with a .60 A/R ratio and a .96 A/R ratio on the turbine side. The compressor’s inducer diameter is about 54 mm and the turbine’s exducer diameter is about 64 mm. The only obvious difference between the T04B90 turbo and this one is the offset exhaust flange and 3” v-band downpipe connection on this turbine volute.

|

|

|

|

|

|

|

|

The T04B’s inducer is a bit deeper than the T04B90’s so it will be a little harder to fabricate a photo-tachometer probe as I have in the past.

|

|

|

|

|

|

|

|

The compressor and turbine wheel of this turbo seem to be made from nice castings considering the price. Hopefully it will hold up for my purposes and if not I can replace it with a Garrett turbo later on.

|

|

|

|

|

|

|

|

The T04B “straight shot” turbine volute (scroll) should help reduce gas flow friction unlike the “centered” scroll on the T04B90. I have high hopes for this turbo being a perfect fit for the GR-6. We will have to wait and see....

|

|

|

|

|

|

|

|

I now have my goals in sight and most of what I need to get started. I really look forward to putting what I have learned into this new engine. With any luck I will create an engine capable of hundreds of hours of operation without replacing parts to keep it going. Reliability is my ultimate goal ;0)

Please join me again for the continuation of the GR-6 turboshaft engine project. Until then stay inquisitive my friends!!!

Don Giandomenico

|

|

|

|

|

|