|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Posted on May 29, 2011

Note: Since this article has been written there have been many advancements in multi-rotor technology. The electronics used in this article may be outdated and unavailable in the current market. This article remains on this site as a reference and record of the MR1 Hexacopter Project and should be cited accordingly.

Hello again folks!!! Every now and then I run into something that sparks my interest and what I am about to build is no exception. I am talking about a “Hexacopter” multi-rotor style helicopter and up until a couple of months ago I had never seen one. Luckily I was able to fly a “hex” for the first time at a model jet rally earlier this year thanks to it’s owner Clay Sherrow.

I met Clay at the 2011 Tucson Jet Rally which I attended to fly my Boomerang Elan and Skymaster F-16 . I had noticed that he was flying an unusual multi-rotor helicopter that he called a Hexacopter. At first glance the alien like aircraft resembled more of a UFO than a RC helicopter. He had fitted the craft with multicolored LED lights that made it look just like something out of the movie “close encounters of the third kind”!!!

Clay offered me the controls and I hovered the copter for a minute. I wasn’t very good at it but it reminded me of flying traditional RC helicopters so I knew that I could get the hang of it if I had one to play with. That is when I decided I would build my own hexacopter and share my experience with the RC community. This thing was just way too cool to keep a secret!!!

Below is a picture of Clay’s hexacopter flying at the Tucson Jet Rally....

|

|

|

|

|

|

I had asked Clay about the flight control board he was using in his hex and where I could get one. He had told me that the board was built by a Kenneth Duffek and that he would try to arrange a meeting the next day. As luck would have it I was able to meet up with Ken at the jet rally and discuss his control board setup. Turns out that Ken had built a few of these boards for his friends and that he could order more parts to build me one if I wanted.

The following Monday after the jet rally I had contacted Ken and asked if he could build me a board so I could experiment with my own hex. He agreed and in a couple of weeks I had my own hexacopter flight control board :0) I wasted no time in ordering up all of the parts for my own version of the hex that I will call the “MR1” or Multi-Rotor One.......

|

|

|

|

|

|

I had ordered up everything I thought I might need including the brushless motors, speed controls, wiring, carbon fiber booms, aluminum tubing (landing skids), fiberglass sheeting, propellers, hardware and Delrin plastic for the boom clamps.

|

|

|

|

|

|

I had also ordered an FMA Co-Pilot CPD4 unit to experiment with infrared horizontal stabilization later on in the build....

|

|

|

|

|

|

The main component that makes a “Multicopter” fly is the flight control board. Ken Duffek’s board (seen below) is what I will be using to control the six electronic speed controllers that will distribute the power to the brushless motors on my hex. The board has a pair of MEMS or Micro-Electro-Mechanical Systems based gyroscope sensors that communicate with a programmable microcontroller chip.

The microcontroller calculates the information given by the gyros (via the firmware) to adjust the flight attitude of the copter for stabilized flight. The flight control board increases or decreases the speed of the counter-rotating motors (via the Electronic Speed Controllers or ESCs) to adjust the roll, pitch or yaw of the copter making controlled flight possible.

You can purchase a couple consumer versions of this type of board that operate in a similar way. One is the OpenPilot CopterControl Board and also the KKMultiCopter Flight Controller. Both systems are compatible with this project and are quite affordable.

Addendum 9/8/12: I have since switched over to using a DJI Naza-M flight controller which has automatic flight stabilization and GPS Retun-To-Home features (not shown). This new controller is super easy to fly and is fast becoming the industry standard for FPV multi-rotor flying...

|

|

|

|

|

|

|

To start off my build I will need to make an airframe that is lightweight and yet rigid enough to support the batteries, electronics and future payloads of the copter. This frame will also support the six brushless motors that will provide the thrust to lift the copter into the air. It is important that the airframe be fairly rigid for the flight control board to properly sense the ever changing attitude of the copter.

I have decided to use several materials to make my airframe including fiberglass sheeting, carbon fiber tube and Delrin acetal resin plastic. I will make my frame “hub” out of Fiberglass Reinforced Polyester (FRP) which is a cost effective building material that is somewhat flexible and yet strong. A step up from FRP sheeting would be carbon fiber sheeting however the cost would be many times the expense of FRP alternatives.

I plan to use pultruded carbon fiber tubes for my motor booms which will be the lightest and strongest solution for this application (seen below right). The carbon fiber booms will allow for a little flex without permanently bending like an aluminum boom could during a rough landing. To hold the booms to the hub I will use a set of clamps made from an acetal resin plastic called “Delrin” (DuPont trade name) which is a “super plastic” used for all kinds of high tolerance applications (seen below left).

Delrin is extremely easy to machine and is resistant to cracking or deforming under pressure which will be perfect for this build.

|

|

|

|

|

|

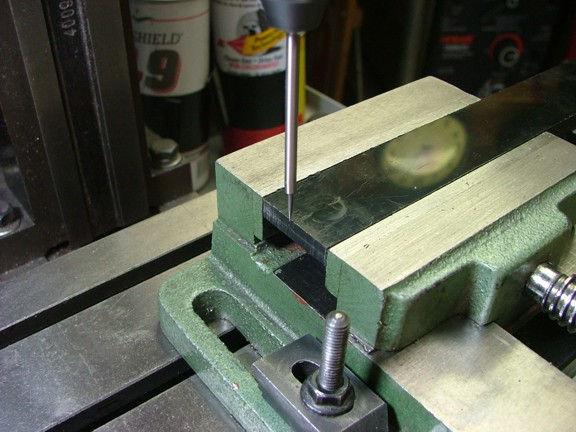

My first step in this build is to machine out a set of boom clamps for the hub frame. These clamps will sandwich the carbon fiber booms and secure them to the hub. I started out with a 1/4” x 1” x 36” long piece of black Delrin acetal resin that I got from McMaster-Carr (Cat# 8662K21). I set up my mill vise on my mill so that the 1” wide Delrin piece was centered on the spindle with my center finder tool (seen below)....

|

|

|

|

|

|

I installed a 1/2” end mill into the spindle and cut into the end of the Delrin to a depth of about .210”. I took note of the table location so the process could be duplicated 23 times using the end of the vise as a reference point.....

|

|

|

|

|

|

The Delrin material machined out nicely :0)

|

|

|

|

|

|

I set up my bandsaw to cut the newly machined clamp at a length of about .450” (I used the end stop to measure the pieces perfectly - seen below). I was then able to start mass producing the clamps by milling out both ends of the 36” long stick of Delrin and the cutting them off in the bandsaw...

|

|

|

|

|

|

In a matter of a hour or so I had all of my 24 boom clamps cut out.....

|

|

|

|

|

|

I used my belt sander to clean up the bandsaw marks on the Delrin pieces before proceeding to the next step. Note: I used a 120 grit belt to smooth out the pieces with a very light pressure....

|

|

|

|

|

|

The next step was to drill out the hardware holes in either end of the clamps. I set up my mill vise to properly locate the 1/8” drill bit in the center of the Delrin material as seen below. I set up the holes on either end of the clamp to be at about .830” center to center..........

|

|

|

|

|

|

After only a few minutes I had all of the boom clamps complete. I weighed all of the clamps to keep track of the running total and came up with 46 grams (1.62 oz)....

|

|

|

|

|

|

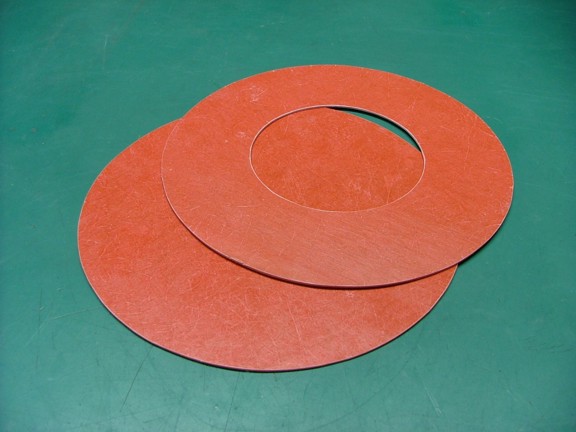

The next step was to cut out the hub disks from the FRP sheeting. In this case I am using a 1/16” thick electrical grade fiberglass sheeting (type GPO3) that is strong yet economical (McMaster-Carr Cat# 8549K52). I layed out two 8” diameter circles on the sheeting and then cut them out on the bandsaw (not shown)...

|

|

|

|

|

|

I also cut out a 4” hole in one of the disks for access to the fuse block and wire loom (more on that later). The disk’s edges were cleaned up with the belt sander as well as a Dremel sanding drum. I weighed the newly completed disks for a total of 155 grams (5.47 oz)....

|

|

|

|

|

|

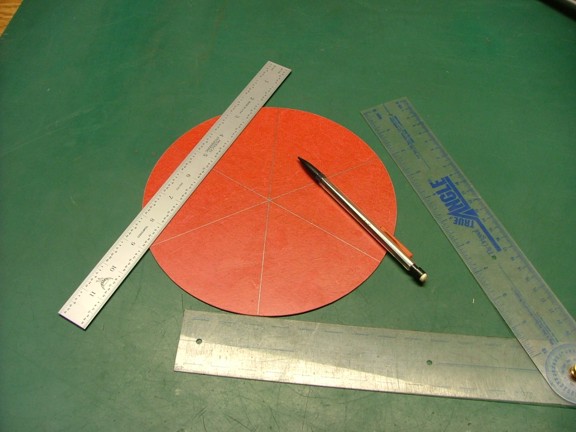

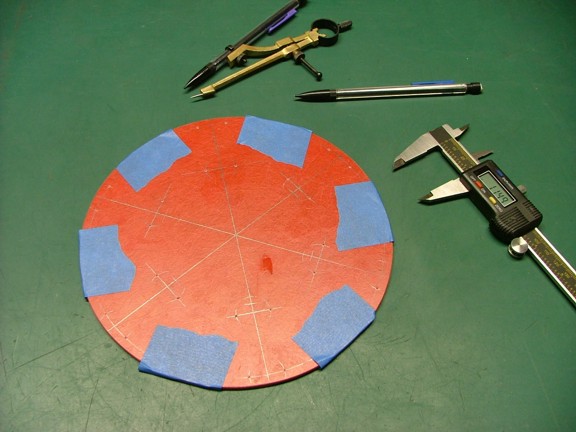

The next step was to mark out where the booms will lay out on the upper hub disk with a protractor. I made 6 - 60° pie wedges on the top of the disk as seen below....

|

|

|

|

|

|

I used a marking compass to lay out the 24 screw hole locations on the upper disk. The inner layout circle was at a diameter of 2.415” and the outer was at 3.965”. I made hash marks at the 60° lines to locate the clamp mounting holes which were layed out to be .415” from the boom centerline (.830 hole to hole). It sounds much more complicated that it is :oP

|

|

|

|

|

|

I used a center punch to mark out the hole centers on the top disk and then taped the upper disk to the lower one for drilling. An 1/8” drill bit was used to drill out all of the screw holes as seen below.....

|

|

|

|

|

|

I used a file to make marks in the edge of the two disks to identify their orientation to each other (not shown) so they can be paired up later on....

|

|

|

|

|

|

And now I can move on to the carbon fiber booms. For this project I am using a 1/2” OD x .05” wall thickness pultruded carbon fiber tube. I got my tubes from a kite/hobby supplier called Goodwinds.com at a very reasonable price. I picked up 2 - 48” long tubes which will be cut into 6 - 12” pieces for the booms (Goodwinds Cat# 020039). I cut the tube with a Dremel cut-off wheel as seen below. The ends of the tubes were sanded a bit to clean up the edges and then weighed them in for a total of 108 grams (3.81 oz for all six booms).

I cut the booms at 12” so that the 9” props I will be using will have enough clearance from each other (680 mm overall diameter). My theory is that if the props are too close that each motors individual air column will be affected by the adjacent motors column causing inefficiency and turbulence. I am hoping that a spacing of one propeller radius (4.5”) between the props tips should be enough for maximum stability (or that is my theory anyway).....

|

|

|

|

|

|

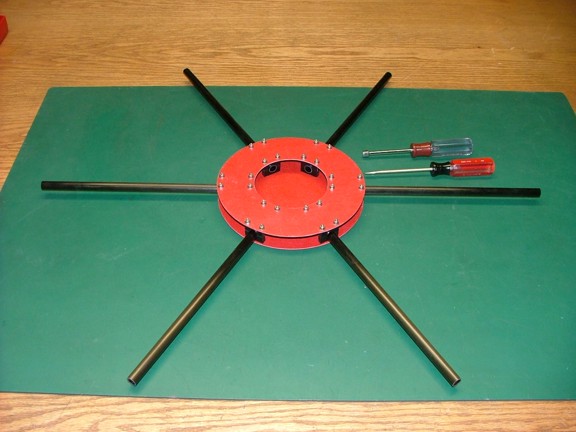

It was now time to assemble the airframe to see if my new boom clamps will work. I installed some 4-40 x 1-1/2” long 18-8 stainless steel screws (McMaster-Carr Cat# 91783A119) and #4 washers (Cat# 92141A005) into the upper hub with the clamps pushed over them as seen below.....

|

|

|

|

|

|

The lower set of clamp was placed over the booms and then sandwiched by the lower hub disk.....

|

|

|

|

|

|

I secured the 4-40 screws with some 316 stainless steel nylon-insert 4-40 locknuts (McMaster-Carr Cat# 90715A005). After adjusting the clamps a bit I decided to remove the 4-40 screws and trim them to be 1-3/8” long (instead of 1-1/2”) so the threads don’t protrude past the lock nuts (not shown). I weighed the total assembly on my digital scale and read 335 grams which equals about 11.82 oz. Not the lightest frame but really sturdy!!!

|

|

|

|

|

|

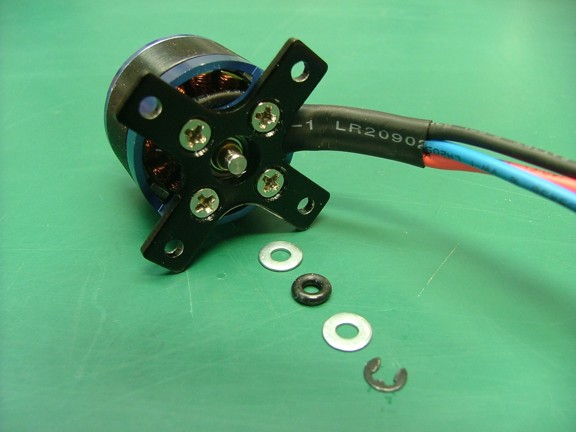

Now that the airframe is looking good I can get started on the motor mounts. For this project I will be using a set of brushless motors from Exceed RC of which I ordered from HobbyParts.com. The motor you see below is a Exceed RC Optima series 370 size brushless outrunner motor (Exceed Cat# 75M13). This 1080 Kv motor is capable of producing 680 grams (24 ounces) of thrust at 16 amps (11.1 volts) using a 9 x 5 x 3-blade prop. The best part is that the motor only weighs 58 grams (2.05 oz) with the prop hub and mounting bracket installed.

Addendum 9/8/12: After many hours of flying the MR1 I have determined that it needed more thrust. In fact I have concluded that the weight to thrust ratio should be closer to 1:1 for better stability. This is why I have upgraded the motors (not shown) to a newer style Exceed RC “Rocket Series” motor (Cat# 86MA69). The 1050 Kv “Rocket” motor can push a 10 x 6 x 3-blade GWS prop at 19 amps which produces over two pounds of thrust!!!. The best part is the new motors only weigh 11 grams more (per motor) that the Optima motor...

|

|

|

|

|

|

It is worth mentioning that these motors cost me less than $15 each :0) The only drawback to using this brand of motor is that the ball bearing tolerance is a little loose which makes these motors a bit noisy at low RPM. However I have since solved this problem by installing an O-ring and two washers under the e-clip on the end of the spindle to create a pre load tension on the bearings (seen below). This setup makes the motors as quiet as any other brushless outrunner.

Note: You can get replacement bearings for these motors at Boca Bearing. They are 0.125” x 0.3125” x 0.1406” in size (Boca Cat# R2-5ZZ).

|

|

|

|

|

|

FYI: The O-ring I used for the tensioner is a Buna-N 15/64” OD x 7/64” ID x 1/16” wide soft O-ring (McMaster-Carr Cat# 2418T111). Note: It is necessary to readjust the length of the protruding shaft to accommodate the washers and O-ring tensioner......

|

|

|

|

|

|

To mount my new motors to the booms I will be making some Delrin motor mount boom clamps which will bolt up to the mounting holes on the brushless motors. I started out by cutting up 12 - 1.3” long x 1” wide x 1/4” thick pieces of Delrin from the leftover stock on the bandsaw....

|

|

|

|

|

|

Using the same layout method as before I drilled two 1/8” holes in either end of the clamps at .925” center to center (matching the mounting holes of the motor brackets I am using).....

|

|

|

|

|

|

After completing all of the 24 holes I was able to clean up the bandsaw marks with my belt sander (not shown)....

|

|

|

|

|

|

The next step was to center the mill vise so that I could drill out the 1/2” hole in the center of the motor mount boom clamps....

|

|

|

|

|

|

I used a thick piece of Delrin as a drill backstop underneath the motor mounts to protect the vise and support the workpiece. I then drilled out all 12 mounts exactly the same way.....

|

|

|

|

|

|

A slot was cut into one side of the motor mounts to act as a clamp when the motor mount screws are tightened. I then weighed the clamps on my scale and read 74 grams (2.61 oz) for all 12 clamps.....

|

|

|

|

|

|

And now to test out my new motor mounts. I gathered up a set of 4-40 screws, washers and locknuts and started assembling the mounts.....

|

|

|

|

|

|

I installed all six of the motor mounts and installed some GWS three blade props to get an idea of how the copter will look. So far so good!!!!

|

|

|

|

|

|

I weighed the entire assembly including the propellers and came up with 870 grams (30.69 oz - 1.92 lbs) which is not too bad considering the motors should be able to lift about 9 pounds at full thrust!! However I want my hex to be reasonably light so I don’t waste too much power in flight. I also want the hex to be light enough to carry a camera for aerial photography and such.

I think I am on the right track and I should be able to get this thing flying before too long. Please join me again when I get into the next phase of construction on the MR1 Hexacopter Project!!!!

Till then take care my friends!!

Don R. Giandomenico

|

|

|

|

|

|

|